WURLITZER STYLE 146 BAND ORGAN RESTORATION PROJECT (Part 10)

by Dr. Bill Black

The restoration project began in October of 2000. This series will mostly be a presentation of the photos that were taken during the restoration process. We wonąt go into great detail in descriptions since the basic restoration process is similar to that described in the 105 restoration series.

PHOTO A - The duplex tracker assembly arrives from Bob Ryeskys

machine

shop after his restoration. This organ was shipped from the factory in

1924 as a late style 146A. A single tracker machine with no bells. Dr.

Moreland tells us that it was converted to a duplex machine sometime

before 1961. He first operated the Carousel in 1961 and it had the

duplex

system then. Original Wurlitzer parts were used for the conversion.

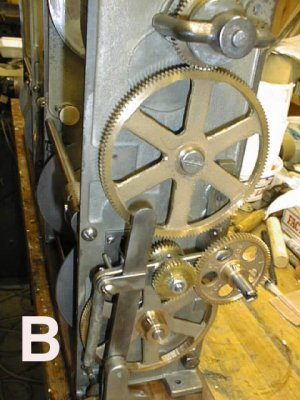

PHOTO B - Bobs restoration included replacement of the worn gears,

bearings and drive shafts. The new large gears were made by Bob using

some blanks which we had cast quite a few years ago.

PHOTO C - A portion of the lower chain sprocket clutch was made by

Wurlitzer out of some type of pot metal casting. This part eventually

fails. Bob machined a replacement for this part.

PHOTO D - Wurlitzer used metal tubing (looks like lead but maybe

some

type of alloy) to connect the wooden tracker bar block to the

transfer block. The diameter of this material appears to be about three

sixteenths of an inch. We want to use the five thirty seconds diameter standard

tracker bar tubing throughout. In order to do this we need to reduce

the hole size in the wooden block to accommodate the five thirty seconds

brass nipples. The holes in the wooden block are drilled out to a

larger size leaving a shoulder in the hole before you get to the change in

angle where the direction of the hole changes. Wooden dowels are glued into

the holes.

PHOTO E - After the glue has dried, the dowels are sanded down

flush with the surface of the wooden block. The dowels are center punched

and then new holes are drilled with a five thirty seconds size drill.

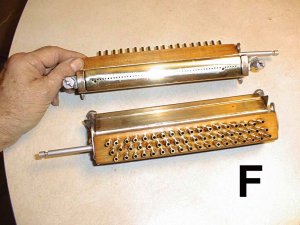

PHOTO F - The completed tracker bar assemblies with the new nipples

and gaskets installed.

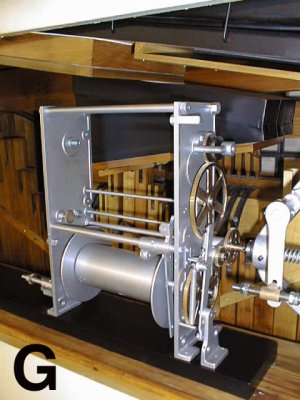

PHOTO G - The mounting board for the roll frames was rather oily so

a

new board was made. The repaired roll frames were again taken apart,

sprayed with silver metallic paint followed with a coat of clear

acrylic to help keep the silver from discoloration. The brass parts were

cleaned with a fine wire brush. The picture shows one of the roll frames being

positioned on the board to determine the correct alignment with the

speed control unit.

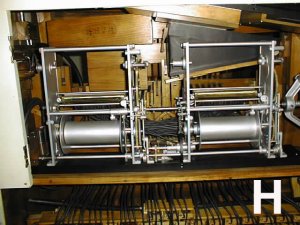

PHOTO H - The completed duplex roll frames installed in the organ.

The tubing from the tracker bar to the transfer block and stack valves

has also been installed.

For more information on the Dr. Floyd L. Moreland Carousel at Casino Pier, visit:

www.casinopiernj.com/index.html

Dr. Bill Black is one of the nation's most knowledgeble Wurlitzer band organ experts. He has made recordings of many band organs and other mechanical music machines which are available for purchase in our Gift Shop . Dr. Bill Black is one of the nation's most knowledgeble Wurlitzer band organ experts. He has made recordings of many band organs and other mechanical music machines which are available for purchase in our Gift Shop .

|