TANGLEY CALLIOPE RESTORATION PROJECT (part 15)

by Dr. Bill BlackDISASSEMBLING THE VALVES

The Tangley Calliope uses a different approach to valve and pneumatic design from that of the Wurlitzer machines. Each Tangley valve and pneumatic are comprised of a single unit. The valve assembly is mounted on the pneumatic and each unit serves a single note on the machine. In PHOTO A, we see an unrestored valve and pneumatic assembly shown as the complete unit and the unit taken apart to show the individual components.

These parts include the pneumatic, the valve body casting, top plate casting, internal movable part of the valve, the pneumatic finger and the gasket. This arrangement allows you to easily service a pneumatic or a valve problem by removing the unit from the face of the stack. Each valve pneumatic unit is independent and removed by unscrewing it from the stack. Servicing the pneumatics on a Wurlitzer machine requires removal of the stack. Unless the Wurlitzer has the unit block valves, stack removal and disassembly is also required to access the valves. So, the ability to remove these individual units for servicing is a very nice feature.

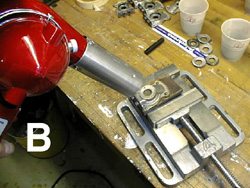

In PHOTO B, we have placed the unit in a small vise to hold it while we take it apart. These valve parts are cast in some type of pot metal so extreme care must be used when working with these parts. There is no source for replacement castings so if you break one you are out of luck. The first step is to remove the top plate. These were glued on with heat sensitive material so the valve was gently warmed with a heat gun till the glue is softened.

In PHOTO C, a knife blade is carefully inserted between the valve body and the top plate. The glue has been softened by the heat gun and the top plate is gently lifted up and off the valve body.

PHOTO D shows the top plate having been removed to expose the movable inner portion of the valve.

In PHOTO E, the four small screws holding the valve body to the pneumatic have been removed. The knife is inserted between the valve body and the wooden top of the pneumatic and the body separated from the pneumatic. It has been a long time since these valves were restored and the glue used was very brittle and the parts came apart very easily with a little pressure from the knife blade.

PHOTO F shows the valve body separated from the wooden pneumatic exposing the pouch well and the leather pouch.

Next month we will replace the leather pouch, recover the pneumatics and reassemble the various parts of the valve assembly.

Dr. Bill Black is one of the nation's most knowledgeble Wurlitzer band organ experts. He has made recordings of many band organs and other mechanical music machines which are available for purchase in our CarouselStores.com website.