WURLITZER CALIOLA RESTORATION (Part 2)

DISASSEMBLY OF THE CALIOLA

by Dr. Bill Black

In 1928, Wurlitzer began the production of a new organ named the CALIOLA. The machine is patterned after their usual band organ format but this machine has a single voice, 44 pipes, one pipe for each playing note.

The Caliola has the motor mounted on the top of the case (PHOTO A) .

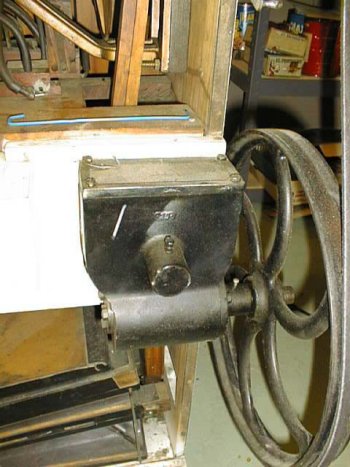

The original configuration used a flat leather belt arrangement connected

to a large pulley mounted on a gear box (PHOTO C). This has been replaced

with a v-belt connected directly to the motor pulley without the use of a

counter shaft mounted on the top of the case. The large pulley has a

slight crown on it and if the motor pulley is mounted in good alignment

the large pulley, the v-belt stays on the pulley during operation. The Caliola has the motor mounted on the top of the case (PHOTO A) .

The original configuration used a flat leather belt arrangement connected

to a large pulley mounted on a gear box (PHOTO C). This has been replaced

with a v-belt connected directly to the motor pulley without the use of a

counter shaft mounted on the top of the case. The large pulley has a

slight crown on it and if the motor pulley is mounted in good alignment

the large pulley, the v-belt stays on the pulley during operation.

The top of the Caliola is made in two pieces. The back piece of the top

is used to mount the vacuum pump. If the pump needs to be removed, this

allows you to remove the pump with that piece of the top after you have

disconnected the pumps sticks and hoses. No need to remove the whole top

to get at the pump. The top of the Caliola is made in two pieces. The back piece of the top

is used to mount the vacuum pump. If the pump needs to be removed, this

allows you to remove the pump with that piece of the top after you have

disconnected the pumps sticks and hoses. No need to remove the whole top

to get at the pump.

PHOTO B shows the motor, pump and both pieces of the top removed. PHOTO B shows the motor, pump and both pieces of the top removed.

The top of the gear box has been removed in PHOTO D. The gear box is

bolted to the back board and the gear itself is attached to the crank

with socket set screws. The gear and the box slides off the shaft. It

has oil for lubrication in the box so care is needed to prevent dumping

the oil on the floor.

PHOTO E shows the speed control unit connected to the roll frame. Also

shown in the photo is the mechanism to control the rewind pneumatic and

valve. When the pneumatic collapses, it pulls an arm into position where

it can engage a stud on the rotating drive shaft which depresses the arm

and shifts the roll frame into the rewind mode. PHOTO E shows the speed control unit connected to the roll frame. Also

shown in the photo is the mechanism to control the rewind pneumatic and

valve. When the pneumatic collapses, it pulls an arm into position where

it can engage a stud on the rotating drive shaft which depresses the arm

and shifts the roll frame into the rewind mode.

There is a sleeve (PHOTO F) on the drive shaft which connects the speed

control unit to the roll frame. Removal of a cotter key allows the

sleeve to slide over the shaft and expose the joint to allow removal of

the speed control. You also need to remove the mounting bolts which

connect it to the side of the case and the wooden bearing on the vertical

shaft along with the long bolt to adjust the speed. There is a sleeve (PHOTO F) on the drive shaft which connects the speed

control unit to the roll frame. Removal of a cotter key allows the

sleeve to slide over the shaft and expose the joint to allow removal of

the speed control. You also need to remove the mounting bolts which

connect it to the side of the case and the wooden bearing on the vertical

shaft along with the long bolt to adjust the speed.

Next month, more disassembly.

Dr. Bill Black is one of the nation's most knowledgeble Wurlitzer band organ experts. He has made recordings of many band organs and other mechanical music machines which are available for purchase in our Gift Shop .

|