by Howard Wyman

BUILDING THE CABINET

Now that the windchest and pipes for the band organ had been completed

this seemed to be a good time to start building the cabinet in order to

be able to install not only the windchest but the remaining components as

they are built. I had decided earlier in the project to paint the

cabinet in a manner similar to the later model 105. That allowed me to

use 3/4 inch birch plywood for most of the cabinet. If the builder

chooses to have a finished oak cabinet like the early models he could use

an oak veneered plywood. For the front of the cabinet I used 3/4 inch

clear pine boards doweled and glued together. I started by attaching the

front to the sides using dowels and glue. This was then attached to the

floor of the cabinet using screws. Before installing the floor I laid

out the positions of the pipes that would be installed beneath the floor

and cut the holes for the passage of air to the pipes. It was necessary

to calculate the distance from the holes to the front of the cabinet so

that they would line up with the row of holes in the bottom front of the

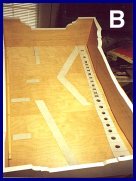

windchest. PHOTO B shows the bottom of the floor and the positions of

the holes. One can also see the suede leather strips on which the pipes

will be glued. I should also mention that I added about three inches to

the height of the sides and front. In adding up the various dimensions

it appeared that there was not enough height to accommodate the tallest

trumpet pipe. As you can see in the photographs this probably would have

been the case.

Now that the windchest and pipes for the band organ had been completed

this seemed to be a good time to start building the cabinet in order to

be able to install not only the windchest but the remaining components as

they are built. I had decided earlier in the project to paint the

cabinet in a manner similar to the later model 105. That allowed me to

use 3/4 inch birch plywood for most of the cabinet. If the builder

chooses to have a finished oak cabinet like the early models he could use

an oak veneered plywood. For the front of the cabinet I used 3/4 inch

clear pine boards doweled and glued together. I started by attaching the

front to the sides using dowels and glue. This was then attached to the

floor of the cabinet using screws. Before installing the floor I laid

out the positions of the pipes that would be installed beneath the floor

and cut the holes for the passage of air to the pipes. It was necessary

to calculate the distance from the holes to the front of the cabinet so

that they would line up with the row of holes in the bottom front of the

windchest. PHOTO B shows the bottom of the floor and the positions of

the holes. One can also see the suede leather strips on which the pipes

will be glued. I should also mention that I added about three inches to

the height of the sides and front. In adding up the various dimensions

it appeared that there was not enough height to accommodate the tallest

trumpet pipe. As you can see in the photographs this probably would have

been the case.

The windchest was then installed in the cabinet. I attached wooden

strips to the inside of the cabinet sides and the windchest rests on

these strips. In the plans it indicates that the chest is held down by

long screws which go through the chest and into the wooden strips.

However screws long enough to do that were impossible to find. Instead I

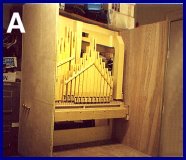

screwed brackets above the chest to hold it down. PHOTO A shows the

windchest installed in the cabinet. With the wind chest in place it was

now possible to determine the position of the air passages in the riser

block. This is the block that contains the passageways from the wind

chest to the pipes beneath the floor. To make a pattern I cut a thick

piece of cardboard of the proper length and with a height which fit

exactly between the front of the windchest and the floor. After putting

it in position I marked the locations of the openings in the bottom of

the windchest and also the openings in the floor. I then removed it from

the organ and drew in the locations of the passages to connect the upper

holes to the corresponding lower holes. This pattern was then used to

make the riser block.

The windchest was then installed in the cabinet. I attached wooden

strips to the inside of the cabinet sides and the windchest rests on

these strips. In the plans it indicates that the chest is held down by

long screws which go through the chest and into the wooden strips.

However screws long enough to do that were impossible to find. Instead I

screwed brackets above the chest to hold it down. PHOTO A shows the

windchest installed in the cabinet. With the wind chest in place it was

now possible to determine the position of the air passages in the riser

block. This is the block that contains the passageways from the wind

chest to the pipes beneath the floor. To make a pattern I cut a thick

piece of cardboard of the proper length and with a height which fit

exactly between the front of the windchest and the floor. After putting

it in position I marked the locations of the openings in the bottom of

the windchest and also the openings in the floor. I then removed it from

the organ and drew in the locations of the passages to connect the upper

holes to the corresponding lower holes. This pattern was then used to

make the riser block.

I made the riser block by forming a sandwich of 1/4 inch plywood on each

side of 3/4 inch wood. The 3/4 inch wood is cut to form the passageways

and glued onto one of the pieces of plywood. The other piece of plywood

is then glued onto the remaining side. There should be no leakage from

one passageway to the next. After the riser is glued together the

passageways should be sealed with shellac or some other sealer. I used a

product called Phenoseal which I obtained from The Player Piano Co.

Next, the riser was attached to the floor with the air passages lined up

with the holes in the floor. The plan is rather sketchy as to how the

riser is attached. I used screws up through the floor and into the

bottom of the riser.

I made the riser block by forming a sandwich of 1/4 inch plywood on each

side of 3/4 inch wood. The 3/4 inch wood is cut to form the passageways

and glued onto one of the pieces of plywood. The other piece of plywood

is then glued onto the remaining side. There should be no leakage from

one passageway to the next. After the riser is glued together the

passageways should be sealed with shellac or some other sealer. I used a

product called Phenoseal which I obtained from The Player Piano Co.

Next, the riser was attached to the floor with the air passages lined up

with the holes in the floor. The plan is rather sketchy as to how the

riser is attached. I used screws up through the floor and into the

bottom of the riser.

To prevent air leakage I glued a leather gasket to

both the bottom and top of the riser before installing it. The windchest

was then secured to the top of the riser block. As I stated earlier I

was not able to obtain screws long enough to do this. Instead I used 1/4

inch lag screws. A countersink has to be drilled in the top of the chest

so that the top of the head of the lag screw is flush with the top of the

windchest. A couple of the screws are located underneath the strip which

holds the piccolos and flageolets so the heads have to be countersunk.

This also means that the strip has to be removed while the windchest is

being anchored down. PHOTO C shows the cabinet with the riser block in

place. The box sitting in the bottom of the cabinet is the blower box

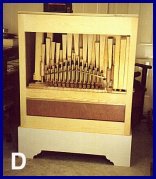

which I used to test individual pipes. Finally, in PHOTO D one can see

the front of the untrimmed cabinet with the wind chest and riser block

installed. Gradually it is beginning to look like a band organ.

To prevent air leakage I glued a leather gasket to

both the bottom and top of the riser before installing it. The windchest

was then secured to the top of the riser block. As I stated earlier I

was not able to obtain screws long enough to do this. Instead I used 1/4

inch lag screws. A countersink has to be drilled in the top of the chest

so that the top of the head of the lag screw is flush with the top of the

windchest. A couple of the screws are located underneath the strip which

holds the piccolos and flageolets so the heads have to be countersunk.

This also means that the strip has to be removed while the windchest is

being anchored down. PHOTO C shows the cabinet with the riser block in

place. The box sitting in the bottom of the cabinet is the blower box

which I used to test individual pipes. Finally, in PHOTO D one can see

the front of the untrimmed cabinet with the wind chest and riser block

installed. Gradually it is beginning to look like a band organ.

Editors note: Howard is a retired electrical engineer and lives in Florida. Most of his career was at the Army Night Vision and Electro-Optics Laboratory. He became involved in mechanical music with the purchase of a non-working player piano. As you will see in his articles, Howard is a highly skilled craftsman. Building your own band organ is a real accomplishment and Howard does beautiful work. Howard can be contacted at: hwyman@tampabay.rr.com